Ungayigcina kanjani i-Atlas Air Compressor Ga132VSD

I-Atlas Copco CA132VVSD iyinhlangano ethembekile futhi ephezulu yokusebenza kahle komoya, yakhelwe ngqo izinhlelo zezimboni ezidinga ukusebenza okuqhubekayo. Ukulungiswa okufanele kwe-compressor kuqinisekisa ukusebenza kahle, impilo yensiza eyengeziwe, nokusebenza kwamandla. Ngezansi umhlahlandlela ophelele wokulungiswa kwe-GA132VSD Air Compressor, kanye namapharamitha asemqoka asemqoka.

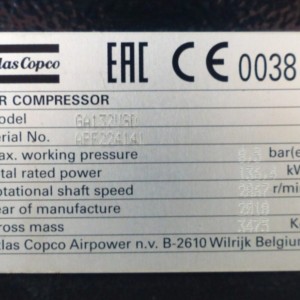

- Isifanekiso: GA132VSD

- Isilinganiso samandla: 132 kW (176 HP)

- Ingcindezi enkulu: 13 ibha (190 psi)

- Ukulethwa komoya kwamahhala (fad): 22.7 m³ / min (800 cfm) ku-7 bar

- Amandla kagesi wemoto: 400V, 3-Phase, 50hz

- Ukuthuthwa komoya: 26.3 m³ / min (927 cfm) ku-7 bar

- I-VSD (i-drive drive eguquguqukayo): Yebo, iqinisekisa ukusebenza kahle kwamandla ngokulungisa isivinini semoto ngokususelwa ekufunweni

- Ileveli yomsindo: 68 db (a) ngemitha eyi-1

- Isisindo: Cishe ama-3 500 kg (7,716 lbs)

- Ubukhulu: Ubude: 3,200 mm, ububanzi: 1,250 mm, ukuphakama: 2 000 mm

1. Amasheke wokulungiswa kwansuku zonke

- Bheka izinga lamafutha: Qinisekisa ukuthi izinga lamafutha ku-compressor lanele. Amazinga kawoyela aphansi angadala ukuthi i-compressor isebenze ngokungasebenzi kahle futhi yandise ukugqokwa kwezakhi ezibucayi.

- Hlola izihlungi zomoya: Hlanza noma ungene esikhundleni sokuhlunga kokuthambisa ukuqinisekisa ukuhamba komoya okungavinjelwe. Isihlungi esivinjelwe singanciphisa ukusebenza futhi sikhuphule ukusetshenziswa kwamandla.

- Bheka ukuvuza: Hlola njalo i-compressor nganoma yimuphi umoya, uwoyela, noma ukuvuza kwegesi. Ukuvuza akugcini nje ngokunciphisa ukusebenza kepha kubangela izingozi zokuphepha.

- Gada ingcindezi yokusebenza: Qinisekisa ukuthi i-compressor isebenza ekucindezelweni okulungile njengoba kuboniswe yi-Pressure Gauge. Noma yikuphi ukuphambuka kusuka ekucindezelweni okusebenzayo okunconyiwe kungakhombisa inkinga.

2. Ukulungiswa kwamasonto onke

- Hlola i-VSD (i-Drayivu yejubane eliguqukayo): Yenza ukuhlolwa okusheshayo ukubheka noma imiphi imisindo engajwayelekile noma ukudlidliza ohlelweni lwe-motor and drive. Lokhu kungakhombisa ukungahambi kahle noma ukugqoka.

- Hlanza uhlelo lokupholisa: Bheka uhlelo lokupholisa, kufaka phakathi abalandeli bokupholisa kanye nabashisi bokushisa. Hlanza ukuze basuse ukungcola kanye nemfucumfucu engadala ngokweqile.

- Hlola imisele ye-condensate: Qinisekisa ukuthi imisele ye-condensate isebenza kahle futhi ingenama-blockages. Lokhu kuvimbela ukunqwabelana kwamanzi ngaphakathi kwe-compressor, engadala ukugqwala nokulimala.

3. Ukulungiswa kwanyanga zonke

- Buyisela izihlungi zomoya: Kuya ngemvelo yokusebenza, izihlungi zomoya kufanele zishintshwe noma zihlanzwe njalo ngenyanga ukuvikela ukungcola nezinhlayiya kusuka ekungeneni i-compressor. Ukuhlanza njalo kufinyelela impilo yesihlungi kanye nokuqinisekisa ikhwalithi yomoya engcono.

- Hlola ikhwalithi kawoyela: Bheka uwoyela nganoma yiziphi izimpawu zokungcola. Uma uwoyela ubonakala ungcolile noma usludi, sekuyisikhathi sokuwushintsha. Sebenzisa uhlobo lwamafutha anconyiwe ngokwemihlahlandlela yomenzi.

- Hlola amabhande nama-pulleys: Bheka isimo nokungezwani kwamabhande nama-pulleys. Qinisa noma ungene esikhundleni kunoma yikuphi okubonakala kugqokwa noma okulimele.

4. Ikota yekota

- Buyisela izihlungi zamafutha: Isihlungi samafutha kufanele sithathelwe indawo njalo ezinyangeni ezintathu, noma ngokususelwa ezincomeni zomkhiqizi. Isihlungi esivinjelwe singaholela ekuthambekeleni kabi kanye nokugqoka ngaphambi kwesikhathi.

- Bheka izinto ezihlukanisayo: Izinto ezihlukanisayo zomoya womoya kufanele zihlolwe futhi zithathwe kabusha wonke amahora okusebenza angu-1 000 noma anconywe ngumenzi. Isihlukanisi esivinjelwe sinciphisa ukusebenza kahle kwe-compressor futhi sandisa izindleko zokusebenza.

- Hlola imoto ye-drive: Bheka ama-motor windings kanye nokuxhunywa ngogesi. Qinisekisa ukuthi akukho ukuthuthuka noma i-wiring evulekile engadala ukwehluleka kukagesi.

I-5. Ukulungiswa konyaka

- Ukushintshwa kwe-Oyili ephelele: Yenza ushintsho olugcwele lwamafutha okungenani kanye ngonyaka. Qiniseka ukuthi uthatha indawo yokuhlunga kawoyela ngesikhathi senqubo. Lokhu kubalulekile ukuze kugcinwe ukusebenza kahle kohlelo lokugcoba.

- Bheka i-valve yokusiza ukucindezela: Hlola i-valve yokusiza ukucindezela ukuze uqinisekise ukuthi isebenza kahle. Lesi yisici sokuphepha esibucayi se-compressor.

- Ukuhlolwa kwe-compressor block: Hlola i-compressor block ukuthola izimpawu zokugqoka noma ukulimala. Bheka noma imiphi imisindo engajwayelekile ngesikhathi sokusebenza, ngoba lokhu kungakhombisa ukulimala kwangaphakathi.

- Ukulinganisa kohlelo lokulawula: Qinisekisa ukuthi uhlelo lokulawula iCompressor Sokulawula nezilungiselelo zilinganiswa ngokuya ngemihlahlandlela yomenzi. Izilungiselelo ezingalungile zingathinta ukusebenza kahle kwamandla kanye nokusebenza kwe-compressor.

- Sebenza ngaphakathi kwamapharamitha anconyiwe: Qinisekisa ukuthi i-compressor isetshenziswa ngaphakathi kokucacisiwe okuchazwe kule ncwajana, kufaka phakathi ingcindezi yokusebenza kanye nokushisa. Ukusebenza ngaphandle kwale mikhawulo kungaholela ekugqokeni ngaphambi kwesikhathi.

- Qapha ukusetshenziswa kwamandla: I-GA132VSD yenzelwe ukusebenza kahle kwamandla, kepha ukuqapha ukusetshenziswa kwamandla njalo kuzosiza ekuboneni noma yikuphi ukungasebenzi kahle ohlelweni oludinga ukubhekana.

- Gwema ukulayisha ngokweqile: Ungalokothi ulayishe i-compressor noma uyihambise ngaphezu kwemingcele yayo ebekiwe. Lokhu kungadala ukugcwala ngokweqile kanye nomonakalo kwizakhi ezibucayi.

- Isitoreji Esifanele: Uma i-compressor ingasebenzi isikhathi eside, qiniseka ukuyigcina endaweni eyomile, ehlanzekile. Qinisekisa ukuthi zonke izingxenye zigcotshwe kahle futhi zivikelwe ekugqwabeni.

| 2205190474 | Isilinda | 2205-1904-74 |

| 2205190475 | Ihlathi | 2205-1904-75 |

| 2205190476 | Umzimba we-valve omncane | 2205-1904-76 |

| 2205190477 | Intambo enomugqa | 2205-1904-77 |

| 2205190478 | Ithebhuri | 2205-1904-78 |

| 2205190479 | Ithebhuri | 2205-1904-79 |

| 2205190500 | Isembozo sekhibhodi ye-Inlet | 2205-1905-00 |

| 2205190503 | Ngemuva kokuphola okupholile | 2205-1905-03 |

| 2205190510 | Ngemuva kokuphola-nge-WSD | 2205-1905-10 |

| 2205190530 | I-Inlet Filter Shell | 2205-1905-30 |

| 2205190531 | I-Flange (i-airfilter) | 2205-1905-31 |

| 2205190540 | Hlunga Izindlu | 2205-1905-40 |

| 2205190545 | UVessel SQL-CN | 2205-1905-45 |

| 2205190552 | Ipayipi le-airfilter 200-355 | 2205-1905-52 |

| 2205190556 | Fan D630 1.1kw 380v / 50hz | 2205-1905-56 |

| 2205190558 | UVessel SQL-CN | 2205-1905-58 |

| 2205190565 | Ngemuva kokuphola-nge-WSD | 2205-1905-65 |

| 2205190567 | Ngemuva kokuphola okupholile | 2205-1905-67 |

| 2205190569 | O.ring 325x7 Fluororubber | 2205-1905-69 |

| 2205190581 | I-Oyili ebalile-aircooling | 2205-1905-81 |

| 2205190582 | I-Oyili ebalile-aircooling | 2205-1905-82 |

| 2205190583 | Ngemuva kokuphola-aircooling akukho wsd | 2205-1905-83 |

| 2205190589 | I-Oyili ebalile-aircooling | 2205-1905-89 |

| 2205190590 | I-Oyili ebalile-aircooling | 2205-1905-90 |

| 2205190591 | Ngemuva kokuphola-aircooling akukho wsd | 2205-1905-91 |

| 2205190593 | Ipayipi endiza | 2205-1905-93 |

| 2205190594 | Ipayipi kawoyela | 2205-1905-94 |

| 2205190595 | Ipayipi kawoyela | 2205-1905-95 |

| 2205190596 | Ipayipi kawoyela | 2205-1905-96 |

| 2205190598 | Ipayipi kawoyela | 2205-1905-98 |

| 2205190599 | Ipayipi kawoyela | 2205-1905-99 |

| 2205190600 | I-Air Inlet Hose | 2205-1906-00 |

| 2205190602 | Ukukhipha umoya okuguquguqukayo | 2205-1906-02 |

| 2205190603 | Kulufa | 2205-1906-03 |

| 2205190604 | Kulufa | 2205-1906-04 |

| 2205190605 | Kulufa | 2205-1906-05 |

| 2205190606 | U-ring | 2205-1906-06 |

| 2205190614 | Ipayipi lokungena emoyeni | 2205-1906-14 |

| 2205190617 | I-flange | 2205-1906-17 |

| 2205190621 | Ingono | 2205-1906-21 |

| 2205190632 | Ipayipi endiza | 2205-1906-32 |

| 2205190633 | Ipayipi endiza | 2205-1906-33 |

| 2205190634 | Ipayipi endiza | 2205-1906-34 |

| 2205190635 | Ipayipi kawoyela | 2205-1906-35 |

| 2205190636 | Ipayipi lamanzi | 2205-1906-36 |

| 2205190637 | Ipayipi lamanzi | 2205-1906-37 |

| 2205190638 | Ipayipi lamanzi | 2205-1906-38 |

| 2205190639 | Ipayipi lamanzi | 2205-1906-39 |

| 2205190640 | I-flange | 2205-1906-40 |

| 2205190641 | Uxhumano lwe-valve undAder | 2205-1906-41 |

Isikhathi Seposi: Jan-03-2025